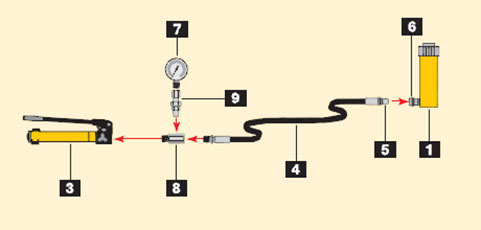

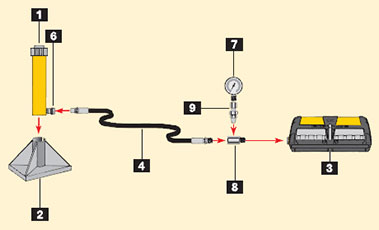

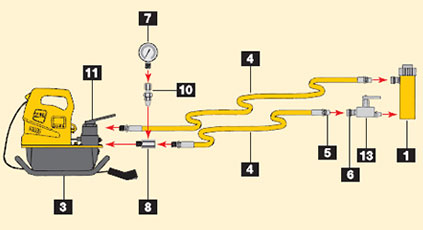

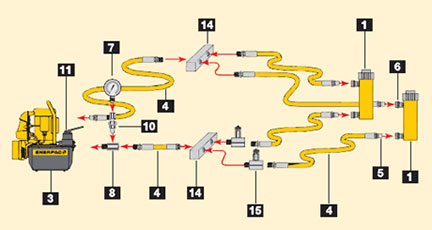

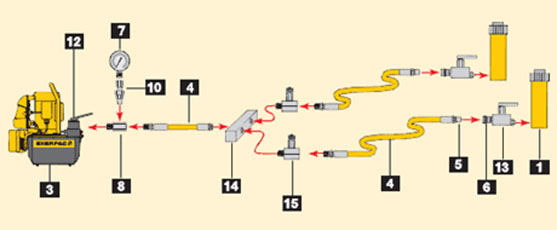

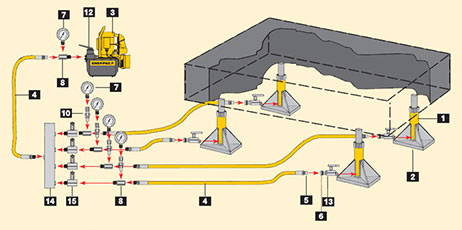

Applies hydraulic force.

For applications such as lifting where additional cylinder stability is required.

Provides hydraulic flow.

Transports hydraulic fluid.

For quick connection of the hose to system components.

For quick connection of the hose end to the system components.

To monitor pressure of the hydraulic circuit.

For quick and easy gauge installation.

Allows proper alignment of valves and/or gauges. Used when units being connected cannot be rotated.

Used to protect gauge from damage due to sudden pulses in the system. Needs no adjustment and allows correct positioning of gauge, prior to tightening.

Controls the direction of hydraulic fluid in a double-acting system.

Controls the direction of hydraulic fluid in a single-acting system.

Controls load descent in lifting applications.

Controls load descent in lifting applications.

Regulates the flow of hydraulic fluid to or from the cylinders.

Hydraulic tooling is used for a wide range of functions across a just about every industrial application imaginable during construction, maintenance, shutdown or demobilisation activities onsite. At Winnellie Hydraulics we specialise in the supply, repair, calibration and hire of this equipment to the oil and gas, mining and all other industries.

As a long term, dedicated Enerpac distributor and service centre Winnellie Hydraulics remain committed to providing our valued customers the best tooling, technical support and training to ensure safety, productivity and reliability in your work place.

Should you see value in the information provided, in proud partnership with Enerpac we can conduct Enerpac Safety Training next time we are on your site. Should you like to see more information please get in touch via sales@winnelliehydraulics.com